APPLICATION

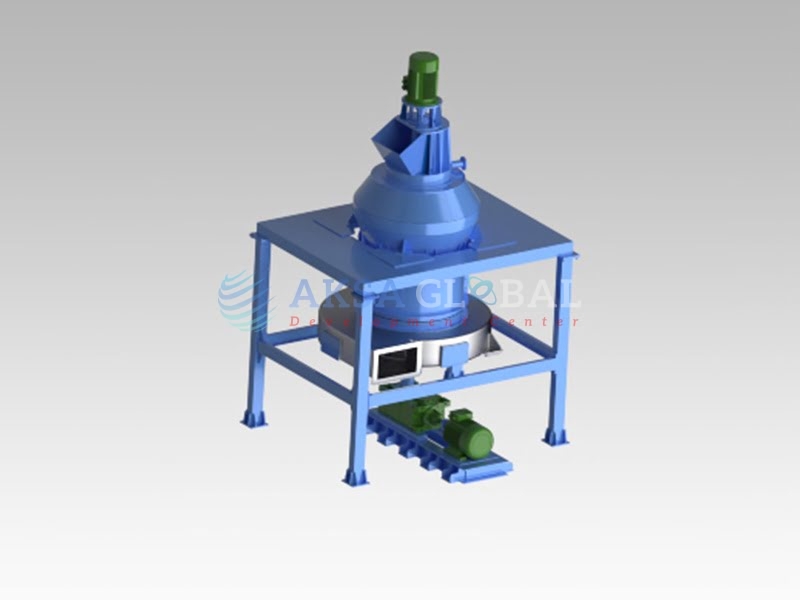

Pendulum ball mills are used for fine grinding of soft to medium-hard materials and for simultaneous drying while grinding. With such a mill, particularly sticky, heat sensitive and very light goods can be milled. Mill capacities vary between 100 kg/h and 80 t/h, depending on the size of the mill and the desired fineness of the product to be milled.

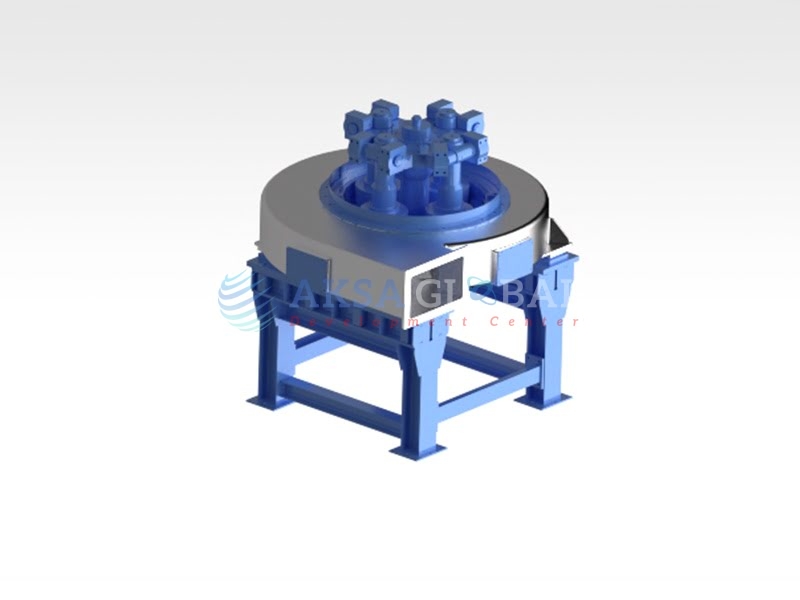

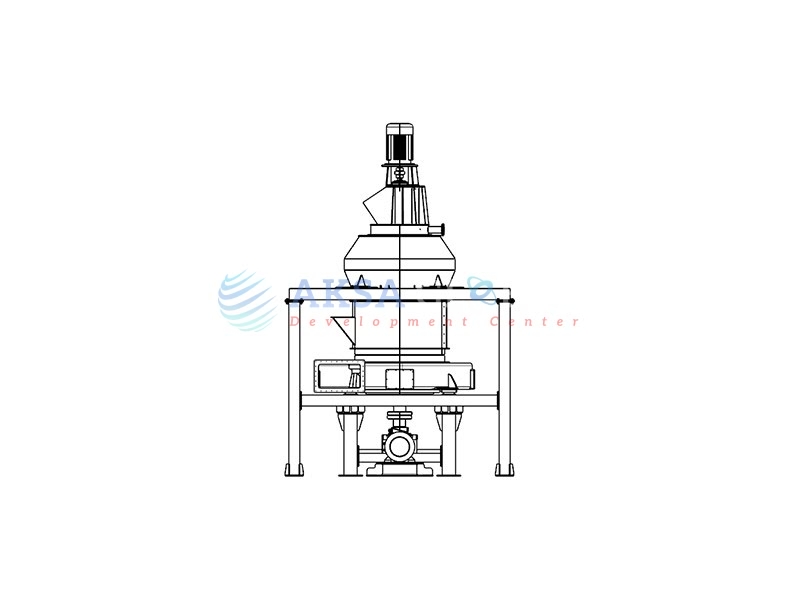

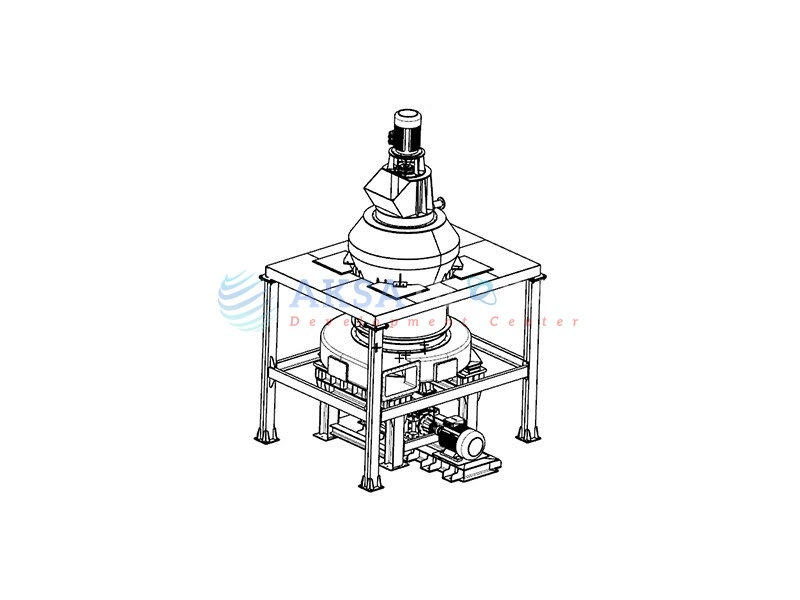

STRUCTURE AND WORKING PRINCIPLE OF THE MILL:

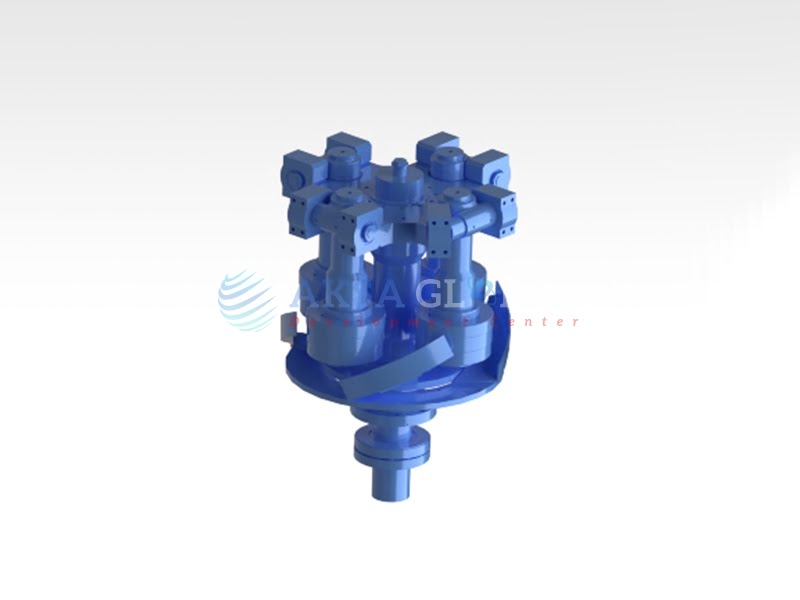

The grinding mechanism consists of the following components;

• Grinding ring: An annular grinding ring in the main body of the mill,

• Pendulum balls: Three or more cylindrical roller shaped balls that can rotate around their own axis, which are placed on a cross-shaped table connected to the upper side of a main shaft with a bearing on the main body in the center of the grinding ring, with joints, and

• Goods feeding paddles: It consists of goods feeding paddles fixed on a tray attached to the underside of the main shaft.

Each shovel rotating with the balls centered on the main shaft scrapes the goods spread on the mill base and feeds the pendulum behind it between the ball and the grinding ring.

Depending on the ware to be grinded, the grinding force to be applied to the trowel is adjusted by changing the mill peripheral speed between 6-8 m/s.

Goods transport and classification mechanism consists of the following components;

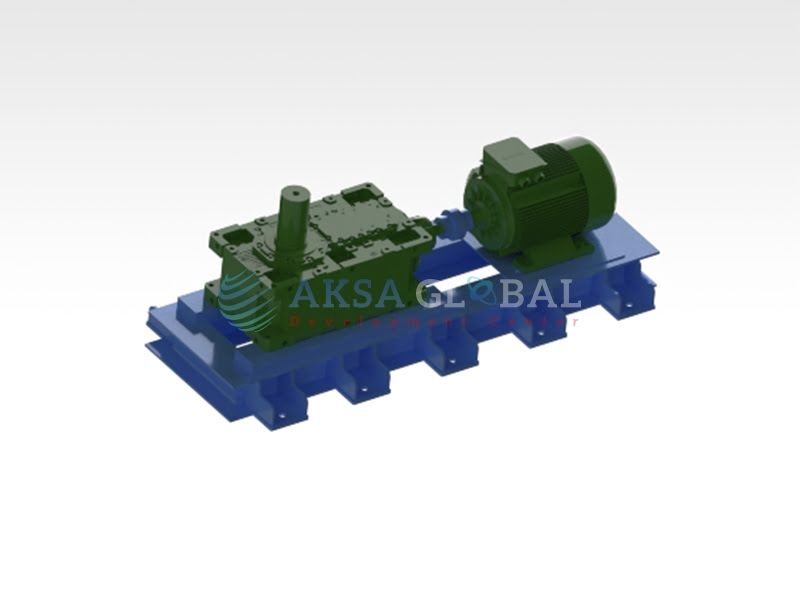

• Radial fan: A radial fan driven by a frequency converter motor, which produces the cold or hot air flow that will carry the grinded product pneumatically to the Separator wheel and then to the dust separator.

• Sorting wheel: Driven separator wheel with frequency converter motor, which sorts the milled goods and

• Dust separator group: It consists of either only jet dust filter, only cyclone or cyclone + filter according to Open-, Closed-, Semi-open-cycle operation.

The air flow provided by a radial fan carries the grinded goods to the separator first, while the coarse goods separated by the separator return to the grinding zone again, after the product leaves the mill with the air flow, the product is kept in a dust trap and the air flow comes to the fan. The air is either vented to the atmosphere or partially or completely returned to the mill, depending on the shape of the cycle.

CARE:

• Continuous Lubrication

• The grinding ring, grinding balls and paddles are made of special wear-resistant steel.

PRODUCT DESCRIPTION

These are the crushers used to break soft and medium-sized materials and obtain between 60-1250 mesh.

usage areas

This machine can be used in chemical fertilizer, chemical product and mining industry with non-flammable and non-explosive barite, limonite, ceramics, etc. with a hardness below 9.3 mosh and a humidity of less than 6%. Used to grind materials.

WORKING PRINCIPLE

The Pendulum Ball Mill is based on the rotation of the revolving balls by leaning against a steel ring and the grinding of the material in between. By adjusting the fan speed of the mill, it is ensured that the product is obtained in the desired fineness.

SOME MATERIALS THAT CAN BE GRIND:

• Activated carbon

• Barytes

• Bentonite

• Dolomite

• Graphide

• Calcined Pet Coke

• Calcium Oxidev

• Calcium Silicate

• Kaolen

• Clays

• Limestone

• Coal

• Manganise Oxide

• Magnesite

• Perlite

• Sulphur

• Talc

• Soapstone

• Titanium Dioxide